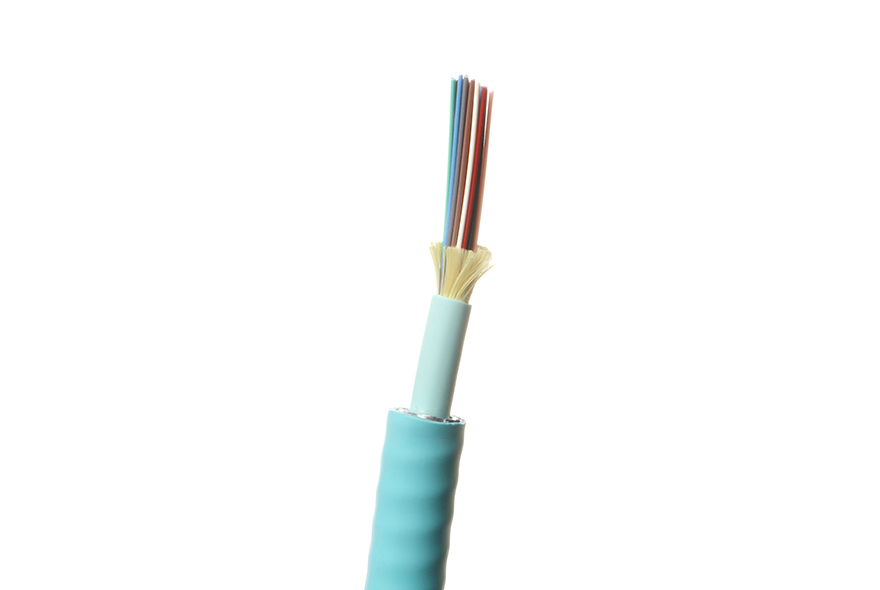

B-Series Breakout – Riser Rated Cables

Installation zone RECOMMENDATION1

1

1

1

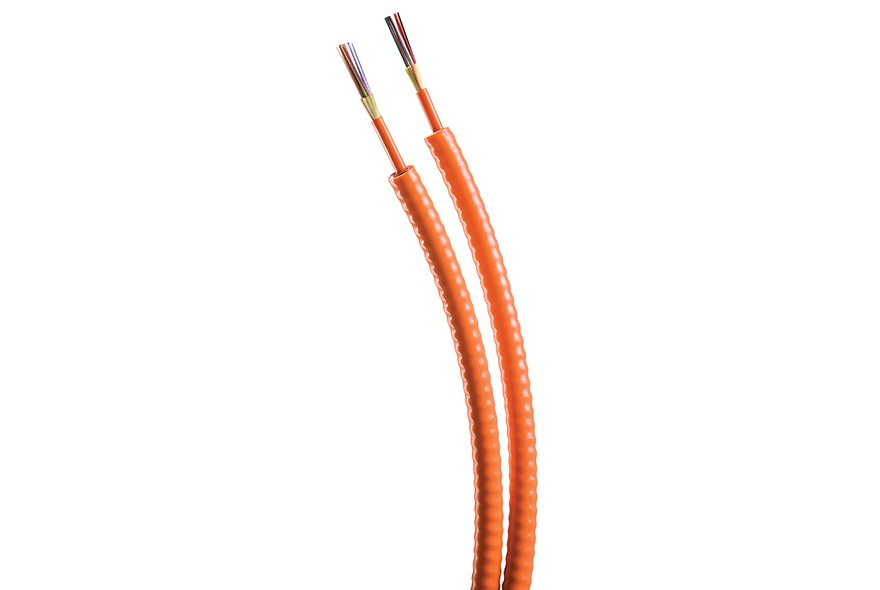

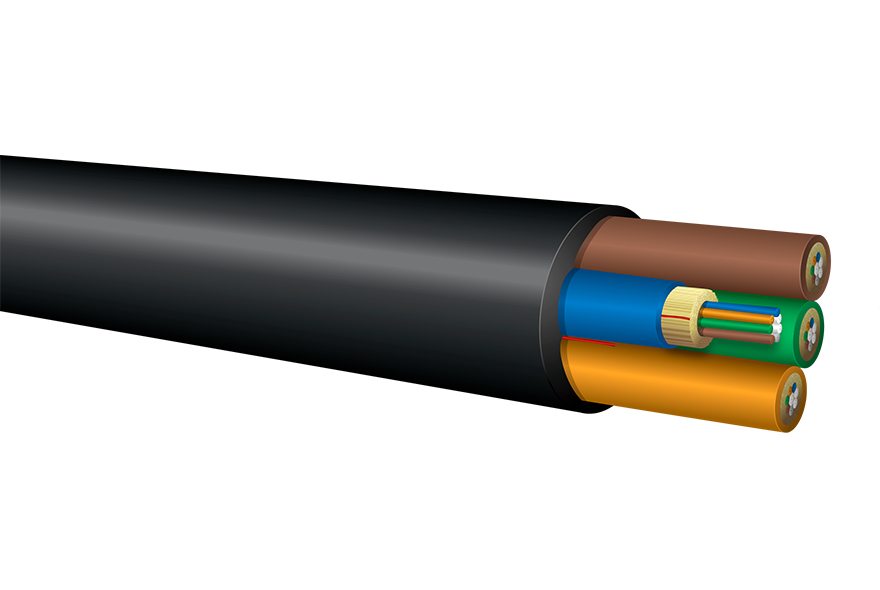

- Ideal for installations requiring an extremely rugged and reliable cable design where maximum mechanical and environmental protection are necessary

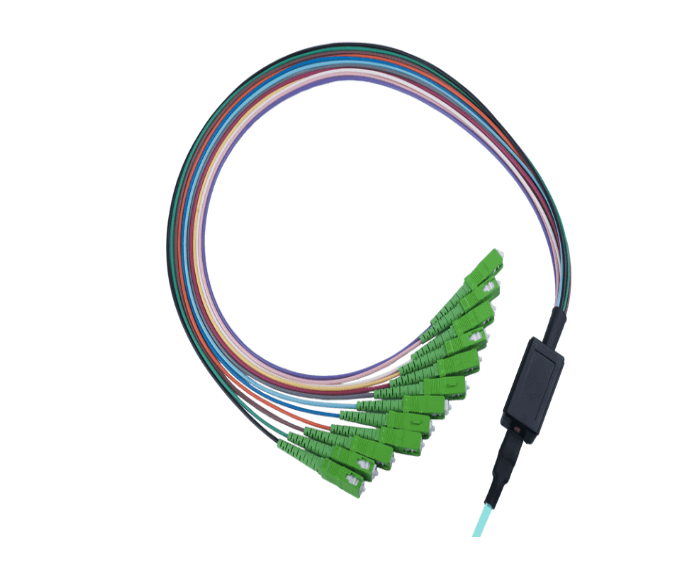

- Easiest cable to install where direct termination of the subcable to a connector and a direct run to panels and equipment are desired

- Direct termination to subcable may eliminate the need for patch panels and patch cords and reduce connector loss

- 900μm buffer eliminates the need for costly and time-consuming installation of fanout kits or pigtail splices, because connectors terminate directly to the subcable

- High crush resistance may eliminate the need for innerduct

Applications

- Fiber Optic tray Cable: Suitable for use in cable trays

- Ideal for installations requiring an extremely rugged and reliable cable design where maximum mechanical and environmental protection are necessary

- Easiest cable to install where direct termination of the subcable to a connector and a direct run to panels and equipment are desired

COST SAVINGS

- Direct termination to subcable may eliminate the need for patch panels and patch cords and reduces connector loss

- 900 µm buffer eliminates the need for costly and time-consuming installation of fanout kits or pigtail splices because connectors terminate directly to the subcable

- High crush resistance may eliminate the need for innerduct

Features

- High performance components and construction

- UL Listed in accordance with NEC sections 770.179(b) for use in vertical runs in building riser shafts or from floor to floor

- Most rugged and easy to install cable design for enterprise cabling applications

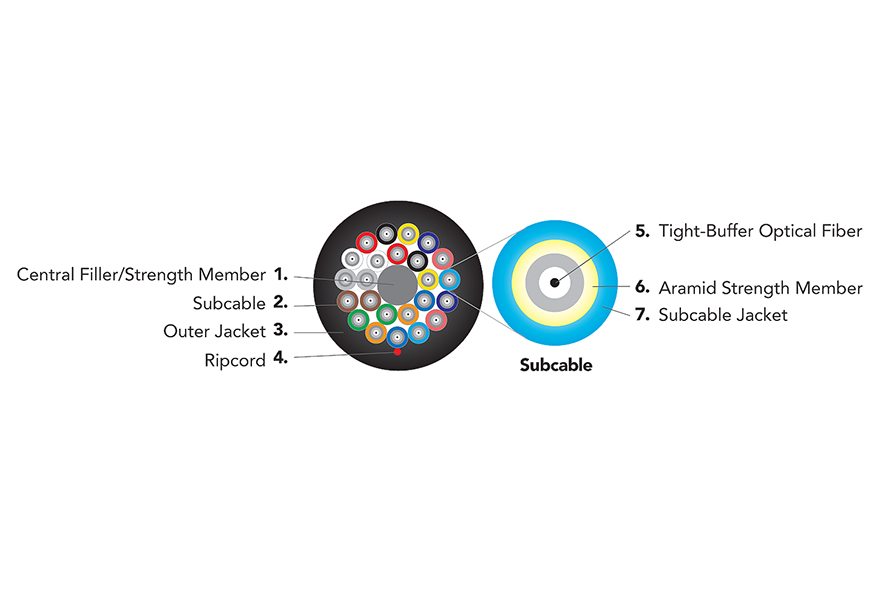

- Core-Locked® outer jacket design for installation survivability and long-term, trouble free service

- Ideal for use in long, vertical installations

- 2.5mm subcables can be direct-terminated with standard connectors (2.0mm and 2.9mm subcables also available)

- Subcabled fiber is environmentally and mechanically protected

- Ideal for use in point-to-point runs in adverse environments

- Direct termination to subcable provides additional strain relief for better connector retention during moves, adds, and changes

- Design is ideal for direct pulling with mesh grips

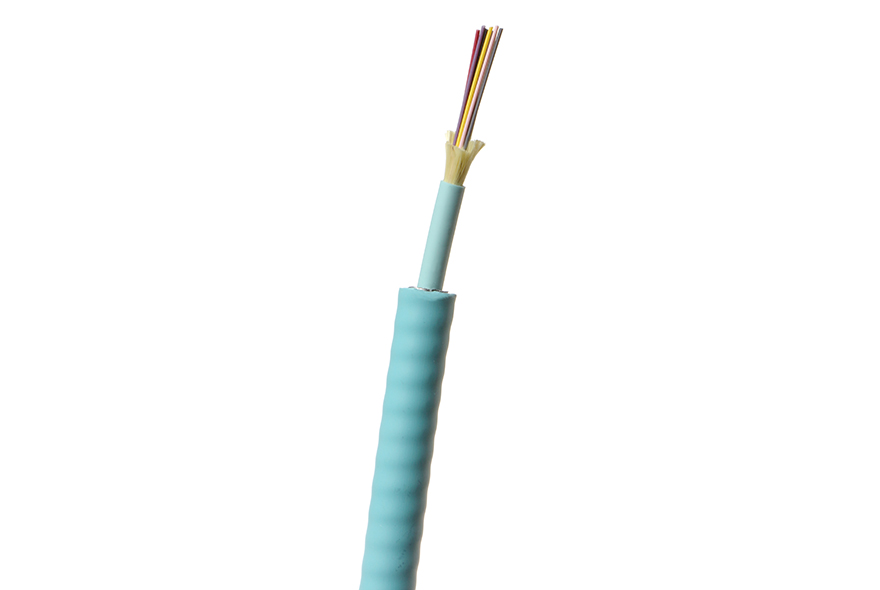

- Cable materials are Indoor/Outdoor - UV, water and fungus resistant

- Wide operating temperature range of -40°C to +85°C

- High performance 900 µm tight-buffered coating on each optical fiber for environmental and mechanical protection

- Interlocking armor can be applied to cables as an alternative to conduit installation

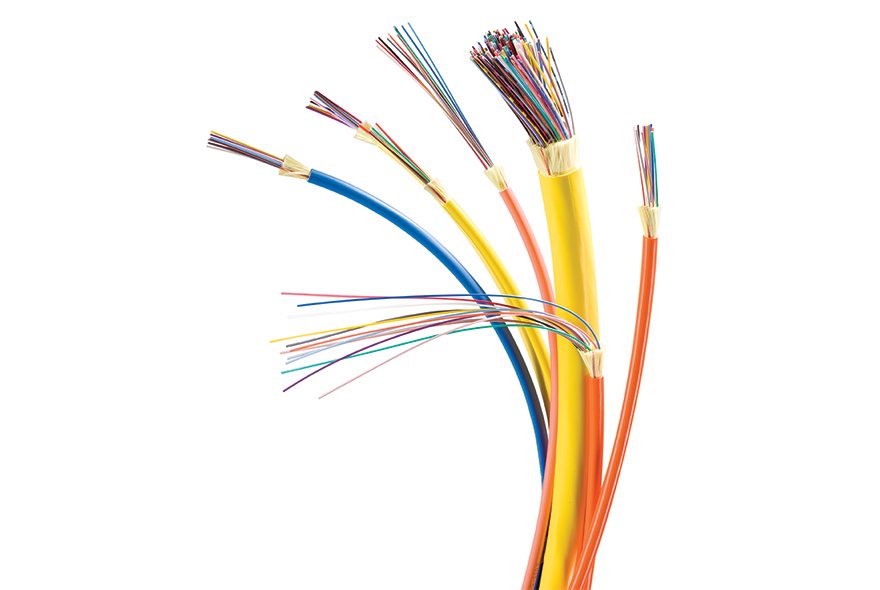

- 2 to 72 fibers

Characteristics

| Characteristic | 2.5mm subcables | 2.0mm subcables |

|---|---|---|

| Operating Temp | -40°C to +85°C | -40°C to +85°C |

| Storage Temp | -55°C to +85°C | -55°C to +85°C |

| Install Temp | -10°C to +60°C | -10°C to +60°C |

| Flame Retardancy | UL Listed Type OFNR (UL 1666) and FT4 (CSA C22.2 No. 232) | UL Listed Type OFNR (UL 1666) and FT4 (CSA C22.2 No. 232) |

| Crush Resist | 2200 N/cm | 2200 N/cm |

| Impact Resist | 1500 impacts | 1500 impacts |

| Flex Resist | 2000 cycles | 2000 cycles |

| Jacket Type | D | D |

Standards

Optical Cable Corporation Indoor/Outdoor tight-buffered fiber optic cables meet the functional requirement of the following standards:

- UL 1651

- UL 1666

- GR-409-CORE

- ICEA-S-104-696

- ICEA-S-83-596

- TIA-568

- TIA-598

Specifications

2.5mm subcables

| Tensile Load | Minimum Bend Radius | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Fiber Count | Part Number | Part Number Configurator | Diameter mm (in) |

Weight kg/km (lbs/1,000ft) |

Installation N (lbs) |

Operation N (lbs) |

Installation cm (in) |

Longer Term cm (in) |

|

| 2 | BX002D***9*R |

7.0 (0.28) |

41.0 (28.0) |

1,200 (270) |

500 (110) |

10.5 (4.1) |

7.0 (2.8) |

||

| 4 | BX004D***9*R |

8.3 (0.33) |

65.0 (44.0) |

2,000 (450) |

800 (180) |

12.2 (4.8) |

8.3 (3.3) |

||

| 6 | BX006D***9*R |

9.6 (0.38) |

84.0 (56.0) |

3,000 (670) |

1,200 (270) |

14.4 (5.7) |

9.6 (3.8) |

||

| 8 | BX008D***9*R |

11.6 (0.46) |

126.0 (85.0) |

4,000 (900) |

1,700 (380) |

17.5 (6.9) |

11.6 (4.6) |

||

| 12 | BX012D***9*R |

14.1 (0.56) |

159.0 (107.0) |

6,000 (1,350) |

2,500 (560) |

21.2 (8.3) |

14.1 (5.6) |

||

| 18 | BX018D***9*R |

15.3 (0.60) |

216.0 (145.0) |

8,000 (1,800) |

3,500 (790) |

23.1 (9.1) |

15.3 (6.0) |

||

| 24 | BX024D***9*R |

17.6 (0.69) |

279.0 (188.0) |

10,000 (2,250) |

3,800 (850) |

26.5 (10.4) |

17.6 (6.9) |

||

| 36 | BX036D***9*R |

20.9 (0.82) |

360.0 (242.0) |

14,000 (3,150) |

6,000 (1,350) |

31.4 (12.4) |

20.9 (8.2) |

||

| 48 | BX048D***9*R |

24.2 (0.95) |

483.0 (325.0) |

18,000 (4,050) |

7,500 (1,690) |

36.3 (14.3) |

24.2 (9.5) |

||

| 60 | BX060D***9*R |

26.4 (1.04) |

580.0 (390.0) |

22,000 (4,950) |

8,800 (1,980) |

39.6 (15.6) |

26.4 (10.4) |

||

| 72 | BX072D***9*R |

28.9 (1.14) |

738.0 (496.0) |

26,000 (5,845) |

11,000 (2,470) |

43.4 (17.1) |

28.9 (11.4) |

||

2.0mm subcables

| Tensile Load | Minimum Bend Radius | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Fiber Count | Part Number | Part Number Configurator | Diameter mm (in) |

Weight kg/km (lbs/1,000ft) |

Installation N (lbs) |

Operation N (lbs) |

Installation cm (in) |

Longer Term cm (in) |

|

| 2 | BE002D***9*R |

6.0 (0.24) |

37.0 (25.0) |

800 (180) |

200 (40) |

9.0 (3.5) |

6.0 (2.4) |

||

| 4 | BE004D***9*R |

7.0 (0.28) |

49.0 (33.0) |

1,600 (360) |

400 (90) |

10.5 (4.1) |

7.0 (2.8) |

||

| 6 | BE006D***9*R |

8.0 (0.31) |

63.0 (42.0) |

2,400 (540) |

600 (130) |

12.0 (4.7) |

8.0 (3.1) |

||

| 8 | BE008D***9*R |

9.5 (0.37) |

83.0 (56.0) |

3,200 (720) |

800 (180) |

14.3 (5.6) |

9.5 (3.7) |

||

| 12 | BE012D***9*R |

11.0 (0.43) |

103.0 (69.0) |

4,800 (1,000) |

1,200 (270) |

16.5 (6.5) |

11.0 (4.3) |

||

| 18 | BE018D***9*R |

12.5 (0.49) |

148.0 (99.0) |

6,000 (1,350) |

1,500 (340) |

18.8 (7.4) |

12.5 (4.9) |

||

| 24 | BE024D***9*R |

14.7 (0.58) |

208.0 (140.0) |

7,200 (1,600) |

1,800 (400) |

22.1 (8.7) |

14.7 (5.8) |

||

| 36 | BE036D***9*R |

16.8 (0.66) |

253.0 (170.0) |

9,600 (2,100) |

2,400 (540) |

25.2 (9.9) |

16.8 (6.6) |

||

| 48 | BE048D***9*R |

20.1 (0.79) |

368.0 (247.0) |

12,000 (2,700) |

3,000 (680) |

30.2 (11.9) |

20.1 (7.9) |

||

| 60 | BE060D***9*R |

16.8 (0.66) |

289.0 (195.0) |

15,000 (3,400) |

3,750 (850) |

25.2 (9.9) |

16.8 (6.6) |

||

| 72 | BE072D***9*R |

26.0 (1.02) |

623.0 (419.0) |

16,800 (3,800) |

4,200 (900) |

39.0 (15.4) |

26.0 (10.2) |

||

Instruction Sheets

Related Documents

- Catalog- Downloadable (PDF)

- Catalog- Interactive

- EZ-Mate Connectors Product Guide

- F-Link Inter-Connect Brochure

- Laser Ultra-Fox Fiber Performance Chart

Please Login Here to access additional documents.

More Indoor/Outdoor Cables