Typical applications for harsh environment fiber optic cable assemblies in the Oil and Gas market include above-surface (or “top-side”) monitoring and controls for oil and gas rigs, both land and sea based, as well as Geo-seismic exploration equipment. In all cases, the user needs a strong and dependable fiber connection that can be deployed quickly and reliably. Multi-pin hermaphroditic connectors, along with flexible and durable deployable cables manufactured by OCC can be deployed in the most extreme environments where rig operators or exploration teams are working, and all fiber connections can be mated and re-mated with relative ease because of the connectors’ design.

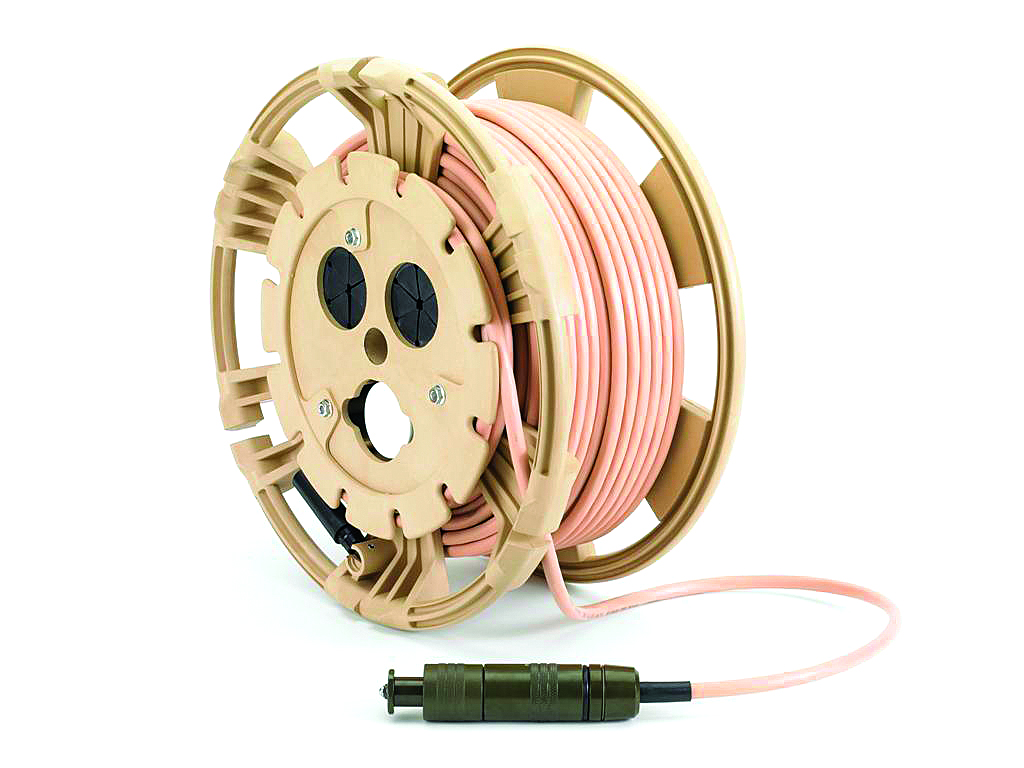

COTS-83526 fiber optic assemblies are widely utilized in the market because multiple manufacturers produce various versions. Often used in deployable military applications, they offer up to 12-channel connectivity with robust and reliable connections in the field for multiple mating cycles. OCC’s COTS-83526 connectors are easily mated to competitor versions, but they offer superior Kevlar retention for better strain relief. OCC’s COTS-83526 connectors can also capture ground wires and cable braids, which are often used by drilling companies for cut resistance, at the receptacle.

EZ-Mate fiber optic cable assemblies offer users up to 24-channel connectivity, and because of their unique design, they can be “blind-mated,” meaning the user can simply twist each end together until they feel the plug mate. Mini Hermaphroditic (MHC-II) fiber optic assemblies offer a similar ease of deployment, but because of their smaller footprint, they can be used in higher-density applications.

Each OCC harsh environment connector utilizes a “physical contact” method of mating fiber channels between termini, and is environmentally sealed for superior mechanical and environmental performance. Their IP-68 rating gives these systems the ability to operate in dirty and wet environments for extended periods of time, and they can easily be cleaned and prepared for re-use if the termini become contaminated in the field. In fact, just like OCC tight-buffered cables, these connectors are designed for use specifically in the dirtiest and wettest of environments and to perform consistently for their users as expected. These connectors are designed to be exposed and survive the oils and chemicals that are likely to be found in oil and gas extraction sites.

Many competitor’s offer expanded beam connectors that mate fiber channels without using a physical contact between termini. Instead, a lens inside the connector expands the light from each fiber channel and sends it over to the corresponding channel on the mated plug or receptacle, where it is refocused and sent into the fiber core. Competitors typically claim these connector systems are better to use in the oil and gas industry because they are easier to clean when they become contaminated. While expanded beam connections are perhaps somewhat easier to clean, they are not very tolerant of dirt or water, including vapor from condensation, rain or fog, being present during operation. In addition, they must be completely dried prior to being placed back in service. In fact, the presence of dirt on a typical expanded beam connection can cause much higher attenuation than similar amounts of dirt on “physical contact” connections like EZ-Mate or COTS-83526. Oily films, constantly present in oil and gas areas, are often difficult to remove from expanded beam lenses. Even fingerprints on lenses can have a negative impact on expanded beam performance. Finally, we have found that expanded beam connectors may not hold up to physical abuse as well as other “physical contact” connectors and are much more susceptible to loss due to shock and vibration, a likely occurrence in seismic exploration applications. Also to note, higher channel counts that allow many fiber links to be connected in one operation generally become very expensive when attempting to use expanded beam.

OCC’s line of hermaphroditic, environmentally sealed connectors and rugged fiber optic cable are ideal for the harsh rigors that fiber optic cable assemblies will experience in the oil and gas industry. Perhaps most important is the fact that OCC offers a vertically integrated solution of cable and connector assemblies for these applications, which means the entire solution can be tailored particularly to an operator’s specific needs.

For more information about OCC harsh environment cable and connectors specifically designed for the Oil & Gas market, contact an OCC Sales Team member – click here.

demanding applications including:

demanding applications including: