Stephen Porach, Manager Business Development for the Enterprise Solutions, has a degree in Mechanical Engineering (BSME) and has worked in the telecommunications industry for over 17 years. He previously worked for SMP Data in a Marketing and Technical Sales role and has held numerous other positions in the electrical, mechanical, and telecommunications markets.

————-

We just returned from the 2012 BICSI Winter Conference, which was one of OCC’s most successful product launches. The Procyon family of pre-terminated fiber cable, fiber enclosures and data center cabinets is the culmination of over a year of soliciting customer feedback and broad industry research.

Data Centers continue to be the fastest growing segment of the telecommunications industry. Recent studies indicate that data centers will continue to experience significant growth for at least the next 5 years. Since 2008, over 50% of the traffic on the internet either originates or terminates in a data center. And, traffic within the data center has more than doubled. This is not limited to just the large data centers owned by Google and Apple, new regulations in the medical industry demand increased data management, state and local governments are digitizing records; all this fuels the need for data centers, large and small. Procyon product line is designed to capture both the fiber and copper infrastructure within that space.

OCC’s Procyon fiber enclosures offer the highest density copper and fiber terminations in the industry. What does this mean, for a 10 Gig fiber application? It means 144 fibers in one rack space. That same enclosure can also handle 1152 fibers supporting a 100 Gig application! Procyon offers a clear migration path for the user as they increase data throughput from 10 Gig to 40 Gig and up to 100 Gig, all with pre-terminated cables and cassettes.

OCC’s engineering team has developed two new fiber optic cable constructions for the Procyon family. The HD cable is an indoor plenum rated high density cable suitable for MPO type terminations. The new HC cable is another of OCC’s popular indoor/outdoor fiber optic cables. Its diameter is 20% less than the competition, and because it does not use ribbonized fiber, it has no preferential bending. Speaking of bend radius…both cables are offered with OCC’s bend tolerant fiber. OCC’s bend tolerant cables offer the best bend radius performance in the industry. This is very important feature as fiber optic cables are now being installed in some very tight spaces.

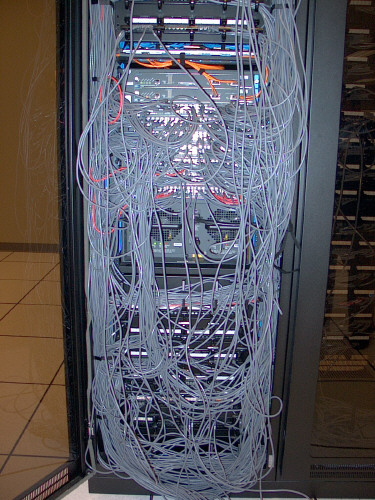

OCC’s new Procyon Data Center cabinets make a great home for our fiber enclosures and cables as well as the servers and switches they will be connected to. These cabinets are 42” in depth and 45 rack units tall. The server cabinet is 24” wide and the switching/patching cabinet is 30” wide, these cabinetsare specifically designed to provide optimal cable management supporting increased cable volume . The cabinets also have several unique features such as angled pdu support brackets which makes it easy to access cable and view displays, easily adjustable front and back mounting rails and PDU mounting brackets which can accommodate popular vendor components. These are just a few of the features offered with the Procyon Data Center cabinet making it the ideal choice to support telecommunications equipment in all applications.

Please take a look in the new 2016 catalog or on the website, or contact a member from the Sales team for more information.