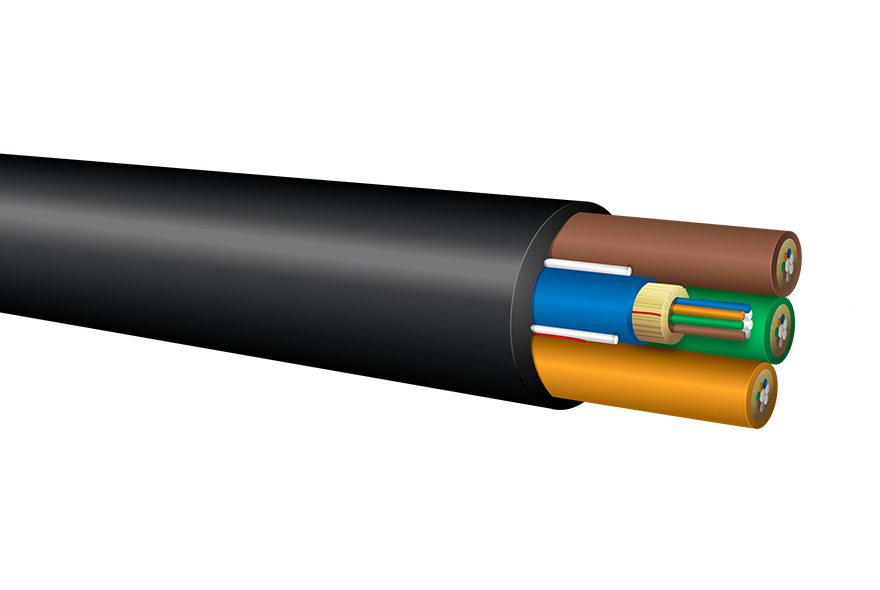

G-Series Subgrouping – MSHA-Rated Mining Cables

Installation zone RECOMMENDATION1

1

1

1

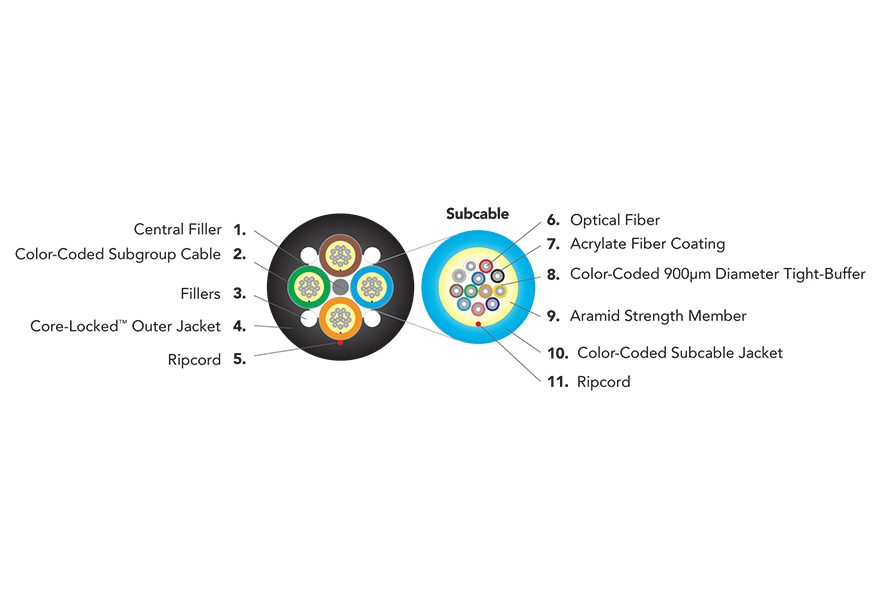

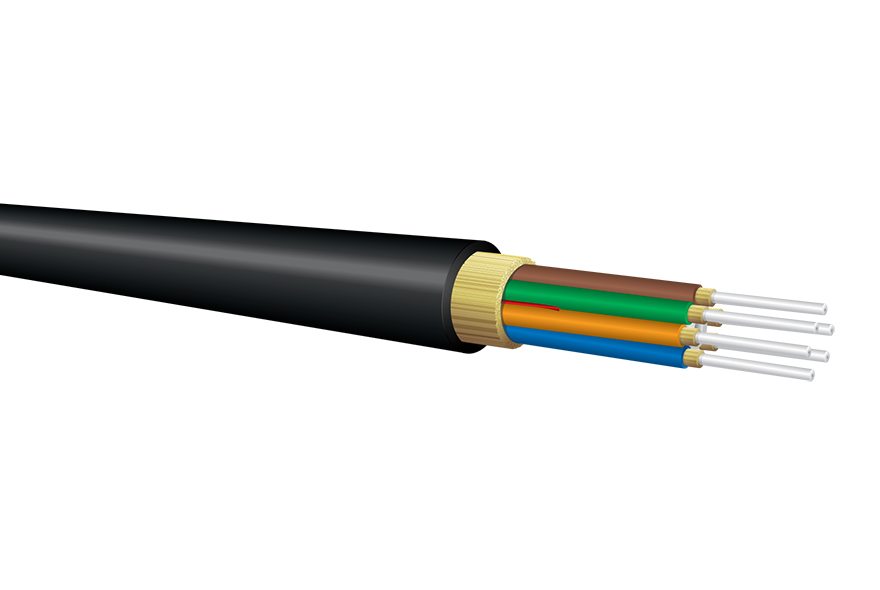

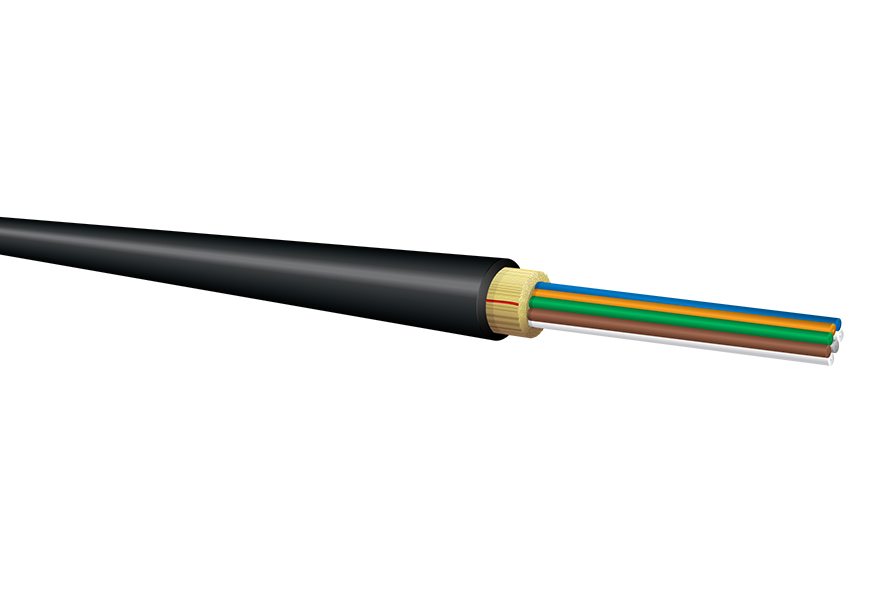

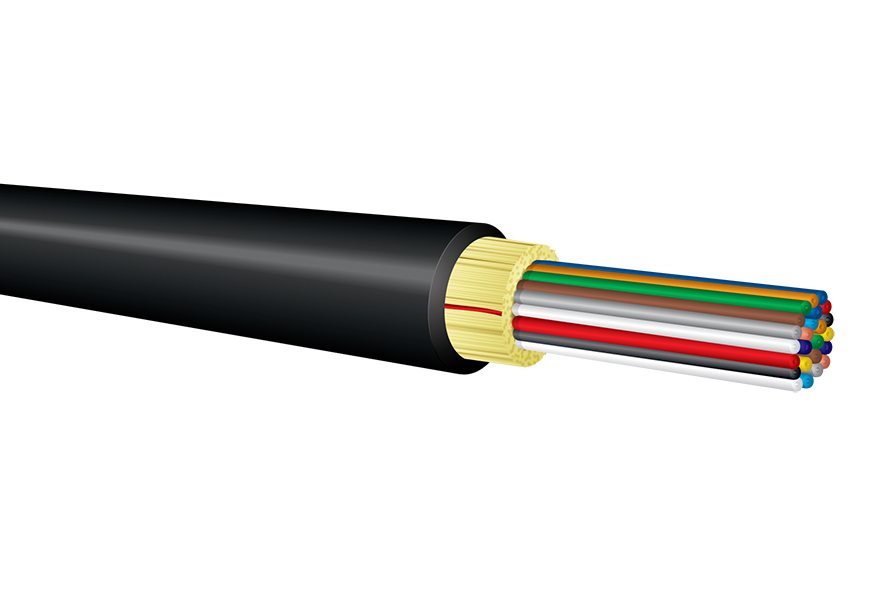

- Ideal separation and identification of single-mode and multimode fibers in a single cable

- Design allows subcables to be routed to multiple locations such as wiring racks and closets

Features

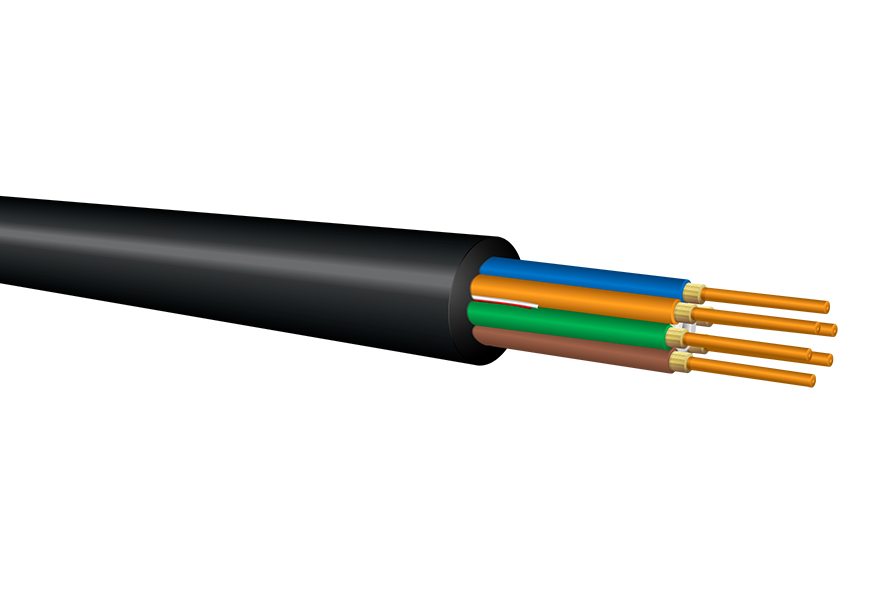

- Tight-buffered multifiber cable design allows subcables to be routed to multiple locations

- Ideal for midspan access applications

- Core-Locked® outer jacket surrounds the subcables for superior crush resistance, survivability, and use in long vertical installations

- UV resistant, water and fungus resistant

- Helically stranded cable core for flexibility, survival in difficult pulls, and mechanical protection for the optical fibers

- High performance tight-buffered coating on each optical fiber for environmental and mechanical protection

- Designed for direct lashing, "J" hook applications, and vertical installations

- Multiple distribution style subcables within a common jacket with each subcable having its own flexible aramid strength member

- Flame retardant - MSHA approved to Part 7, Subpart K of Title 30 Code of Federal Regulations (CFR)

Characteristics

| Characteristic | 5.5mm Subcables | 4.5mm Subcables |

|---|---|---|

| Operating Temp | -40°C to +85°C | -40°C to +85°C |

| Storage Temp | -55°C to +85°C | -55°C to +85°C |

| Install Temp | -10°C to +60°C | -10°C to +60°C |

| Flame Retardancy | MSHA- approved 30CFR 7.408 Signal Cable | MSHA- approved 30CFR 7.408 Signal Cable |

| Crush Resist | 2100 N/cm | 2100 N/cm |

| Impact Resist | 1500 impacts | 1500 impacts |

| Flex Resist | 2000 cycles | 2000 cycles |

| Jacket Type | D | D |

Standards

OCC Indoor/Outdoor tight-buffered fiber optic tray cables meet the functional requirements of the following standards:

- MSHA Approved 30CFR 7.408 Signal Cables

- Part 7, Subpart K of Title 30 Code of Federal Regulations (CFR)

- GR-409-CORE

- ICEA-S-104-696

- ICEA-S-83-596

- TIA-568

- TIA-598

Specifications

12-Fiber (5.5mm) Subcables

| Tensile Load | Minimum Bend Radius | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Fiber Count | Part Number | Part Number Configurator | Diameter mm (in) |

Weight kg/km (lbs/1,000ft) |

Installation N (lbs) |

Operation N (lbs) |

Installation cm (in) |

Longer Term cm (in) |

|

| 24 | GX024D***9*S |

16.6 (0.65) |

243.0 (164.0) |

4,600 (1,030) |

1,500 (340) |

25.0 (9.8) |

16.6 (6.5) |

||

| 36 | GX036D***9*S |

16.6 (0.65) |

240.0 (161.0) |

5,900 (1,330) |

1,050 (440) |

25.0 (9.8) |

16.6 (6.5) |

||

| 48 | GX048D***9*S |

16.6 (0.65) |

237.0 (159.0) |

7,200 (1,620) |

2,400 (540) |

25.0 (9.8) |

16.6 (6.5) |

||

| 60 | GX060D***9*S |

18.4 (0.72) |

308.0 (207.0) |

9,500 (2,140) |

3,150 (710) |

27.6 (10.9) |

18.4 (7.2) |

||

| 72 | GX072D***9*S |

19.2 (0.76) |

330.0 (222.0) |

11,300 (2,540) |

3,750 (840) |

28.9 (11.4) |

19.2 (7.6) |

||

6-Fiber (4.5mm) Subcables

| Tensile Load | Minimum Bend Radius | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Fiber Count | Part Number | Part Number Configurator | Diameter mm (in) |

Weight kg/km (lbs/1,000ft) |

Installation N (lbs) |

Operation N (lbs) |

Installation cm (in) |

Longer Term cm (in) |

|

| 12 | GB012D***9KS |

14.6 (0.57) |

207.0 (139.0) |

3,800 (850) |

1,200 (270) |

21.9 (8.6) |

14.6 (5.7) |

||

| 18 | GB018D***9KS |

14.6 (0.57) |

208.0 (140.0) |

4,700 (1,060) |

1,800 (400) |

21.9 (8.6) |

14.6 (5.7) |

||

| 24 | GB024D***9KS |

14.6 (0.57) |

209.0 (140.0) |

5,600 (1,260) |

1,800 (400) |

21.9 (8.6) |

14.6 (5.7) |

||

| 30 | GB030D***9KS |

15.6 (0.61) |

240.0 (161.0) |

7,500 (1,690) |

2,400 (540) |

23.4 (9.2) |

15.6 (6.1) |

||

| 36 | GB036D***9KS |

16.9 (0.67) |

282.0 (189.0) |

8,900 (2,000) |

2,850 (640) |

25.4 (10.0) |

16.9 (6.7) |

||

| 48 | Please Call OCC for ordering assistance. |

16.6 (0.65) |

237.0 (159.0) |

7,200 (1,620) |

2,400 (540) |

25.0 (9.8) |

16.6 (6.5) |

||

| 60 | Please Call OCC for ordering assistance. |

18.4 (0.72) |

308.0 (207.0) |

9,500 (2,140) |

3,150 (710) |

27.6 (10.9) |

18.4 (7.2) |

||

| 72 | Please Call OCC for ordering assistance. |

19.2 (0.76) |

330.0 (222.0) |

11,300 (2,540) |

3,750 (840) |

28.9 (11.4) |

19.2 (7.6) |

||

Instruction Sheets

Related Documents

- Catalog- Downloadable (PDF)

- Catalog- Interactive

- Laser Ultra-Fox Fiber Performance Chart

- Mining Cables Quick Reference Guide

- Mining Solutions Guide

Please Login Here to access additional documents.

More Mining Cables